|

|

|

|

|

| Principle washer clutch | |

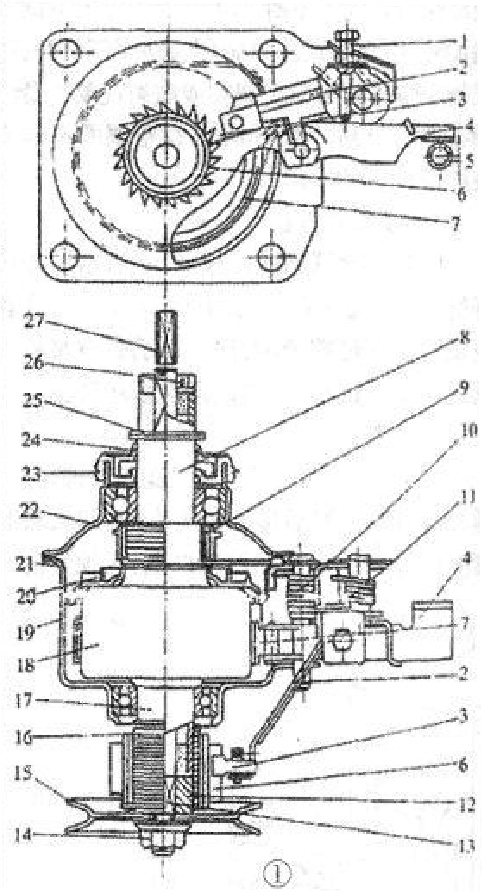

Gear clutch (referred clutch) automatic washing machine is the heart, is a key component of the washing machine and the conversion of dehydration, washing and dewatering can be achieved when two functions work. Clutch structure is more complex, various brands of automatic washing machine clutch structure is basically the same shape.

Commonly used clutch structure diagram as shown, large pulley center square hole, tighten the nut to be fixed on the square surface of the gear shaft, clutch also suits the gear shaft, big pulley, gear shaft and the clutch fused . Clutch outer and coat the outside diameter of the same axis, square wire mounted on the outside diameter of the clutch spring clutch and coat the shaft, the upper side of the wire and tighten the clutch spring in a free state, the lower end of the head tilt, plug in the wall of a small ratchet holes, even as one of the lower and ratchet drive the lower end of the square silk clutch spring rotates ratchet rotation. In the free state party clutch spring smaller diameter wire, square wire spring clutch tighten the clutch and coat the outside diameter of the shaft. Brake package on the planet with an outer diameter of the clutch, brake bands end with screws on the clutch housing, and the other end is fixed to the lower end of the brake lever when the brake lever rotates around the pin, you can relax and tighten brake band. The brake lever can also adjust the clutch lever detent position by the adjusting screw in the radial direction of the ratchet, the pawl extends into or away from the ratchet, so as to change the operating state of the clutch (washing or dehydration).

When washing, the working state of the clutch should be an electromagnet de-energized, the drain valve is closed, with the brake lever positioning sleeve separating the drain valve on the connecting plate. Brake lever in the braking action of the spring, the recovery in situ, with the brake wheel brake to hold fast to make the dehydration shaft does not rotate. While the pawl on the fork springs in the fork action will ratchet dialed an angle, will be installed in the square ratchet clutch spring dial loose wire. When the pulley forward rotation, although a square silk clutch spring is tightened direction, but has been allocated loose, when the pulley in the opposite direction of rotation, square wire spring clutch again dialed loose direction, regardless of the pulley is positive forward or reverse, the washing shaft and the dewatering shaft are not integrally connected. In this case, the dewatering shaft and the brake is a brake band and a torsion spring, the pulley can be driven by the planetary gear reduction mechanism pulsator washing shaft and on which the forward and reverse rotation (180r / min), washed with functions to realize, dehydration dewatering shaft and on which the barrel can not be rotated.

When dehydrated, the drain valve pull power, open the drain valve, solenoid rod fixed to the clutch lever pushes forward brake lever, the brake lever rotates around the pin.

The friction brakes Larsson, so the brakes do not work.

Brake lever also push the adjusting screw, the clutch lever is rotated to drive on it with the ratchet pawl disengage the ratchet and square wire spring is in a free state, the party that is in elastic silk clutch spring tightened state. During dehydration, the barrels clockwise, large pulley and gear shafts, clutch together clockwise rotation of the rotating clutch on the outside diameter of the square silk clutch springs more tightened, resulting in tremendous friction between the two between force, square silk clutch spring and jackets also have a huge shaft friction. Thus, by square silk clutch spring clutch and coat the shaft will be fused. Coat the shaft and gear housings, dewatering shaft through the static and rolling process with law as a whole, dewatering shaft through the other side of the shaft hole with the flange has become one, but also with flange screws on the inner barrel, so the barrels and reducer shell as a whole, large drive pulley rotates inside the barrel feet square silk clutch springs synchronous rotation (900r / min), the dewatering function.

| | | |

|

|

|